欢迎进入山东恒能环保能源设备有限公司

欢迎进入山东恒能环保能源设备有限公司

General situation of biogas desulfurization and dehydration system

沼气脱硫脱水处理工艺

Desulphurization and dehydration process of Biogas

沼气脱硫脱水体系能为脱硫反响供给佳的温度、水气含量,脱硫剂的装填工艺亦能为脱硫过程供给佳的气流通道和气固反响的有用触摸面积,能够极大地进步脱硫剂的使用功率以及沼气的净化程度。通过脱硫后的净化沼气进入沼气增压风机增压运送,一方面战胜管道、设备、管件的阻力丢失,另一方面使运送发电机组前的沼气压力满意机组的进气压力要求。考虑到沼气是一种易燃易爆的危性气体,本方案中选用的增压风机进行了特别的内部处理,以满意防腐、防爆、防走漏的性要求,确保整个脱硫脱水体系的。增压后的沼气进入缓冲罐,完成气液固的有用别离,一起到达进体稳压处理,以满意对发电机组的平稳供气,确保发电机组的、运转。

Biogas desulfurization dehydration system can provide the best temperature and water gas content for the desulfurization reaction. The loading process of desulfurization agent can also provide the best gas flow channel and the useful touch area of gas-solid reaction for the desulfurization process. It can greatly improve the power of desulfurization agent and the degree of biogas purification. The desulphurized methane is transported into the pressurized fan to overcome the loss of resistance of pipes, equipment and fittings, and the methane pressure before being transported to the generating set satisfies the intake pressure requirement of the generating set. Considering that biogas is a kind of flammable and explosive dangerous gas, the turbocharged fan selected in this scheme has carried out special internal treatment to satisfy the safety requirements of anticorrosion, explosion-proof and leakage-proof, and to ensure the safety of the whole desulfurization and dehydration system. The pressurized methane enters the buffer tank, completes the useful separation of gas, liquid and solid, arrives together for the gas stabilization treatment, in order to satisfy the stable gas supply to the generator set and ensure the safe and efficient operation of the generator set.

在乡村大办沼气,既可解决燃料问题,又可改环境卫生、添加有机肥料。此外,还可用以照明、开动内燃机等除恶臭:能去除挥发性有机物(VOC)、无机物、硫化氢、氨气、硫醇类等首要污染物,以及各种恶臭味,脱臭功率可达99.9%以上。

Biogas management in rural areas can solve fuel problems and improve environmental sanitation and organic fertilizers. In addition, it can also be used for lighting, starting internal combustion engines and other high-efficiency deodorization: can effectively remove volatile organic compounds (VOC), inorganic substances, hydrogen sulfide, ammonia, mercaptan and other major pollutants, as well as a variety of odor, deodorization power up to 99.9%.

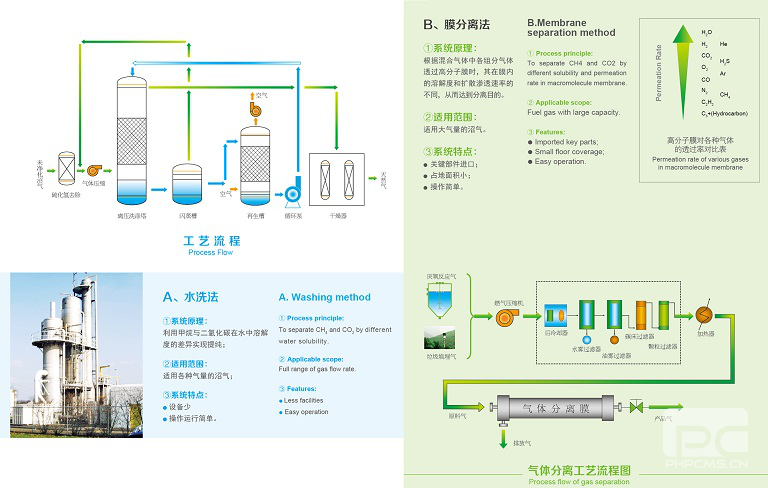

沼气脱硫脱水工艺流程

Biogas desulfurization and dehydration process flow

从厌氧沼气池中出来的沼气中含有很多的的水气、粉尘杂质、硫化氢等有害气体。沼气通过开始脱水除尘后然后进入脱硫塔,使用合理的反响条件可经济地将沼气中的硫化氢脱

Biogas from anaerobic digester contains a lot of harmful gases such as water, dust impurities, hydrogen sulfide and so on. Biogas can be economically dehydrated to hydrogen sulfide by starting dehydration and dust removal and then entering a desulfurization tower under reasonable reaction conditions.

200ppm以下,脱硫后的沼气进入沼气增压风机进行增压运送,增压后的沼气进入缓冲体系进行缓冲,一方面进行沼气除杂处理,另一方面安稳送气压力,以确保后续发电机组的安稳运转,缓冲稳压后的沼气进入终端用气设备。

Under 200 ppm, the desulfurized methane will be transported into the pressurized fan for pressurization, and the pressurized methane will be buffered in the buffer system. On the one hand, the methane will be treated for impurity removal, on the other hand, the gas pressure will be stably supplied to ensure the safe operation of the subsequent generators and the methane will be transported into the terminal gas equipment after buffering and stabilizing.

综上所述有山东恒能环保能源设备有限公司提供,如果想了解更多知识浏览我们官网谢谢支持!

Summarize all the above information provided by Shandong Heneng Environmental Protection Energy Equipment Co., Ltd. If you want to know more about methane desulfurization, visit our official website: http://www.fcw-app.com Thank you for your support!