沼气脱硫设备是什麼沼气脱硫器

What kind of biogas desulfurizer is the biogas desulfurizer?

沼气脱硫优点

Advantages of biogas desulfurization

优点在于多孔管的设置,使与氧化铁小颗粒之间的出气道面积大爲增大,则出气量大;其次水分局部泡烂氧化铁颗粒但仍能留存局部出气孔;再次在于多孔管悬空设置,使脱硫瓶内水分积存在悬空多孔管下方,不容易泡烂多孔管周边的氧化铁颗粒。

The advantages lie in the setting of porous tubes, which greatly enlarges the area of the outlet passage between the small particles of iron oxide and the large amount of air output; secondly, the local foaming of iron oxide particles can still retain the local air outlet; thirdly, the setting of the suspended porous tubes makes the water volume in the desulfurization bottle exist under the suspended porous tubes, and the iron oxide particles around the porous tubes are not easy to bubble and rot.

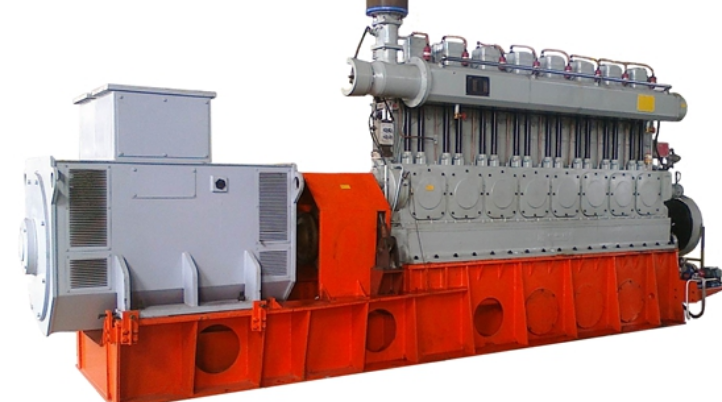

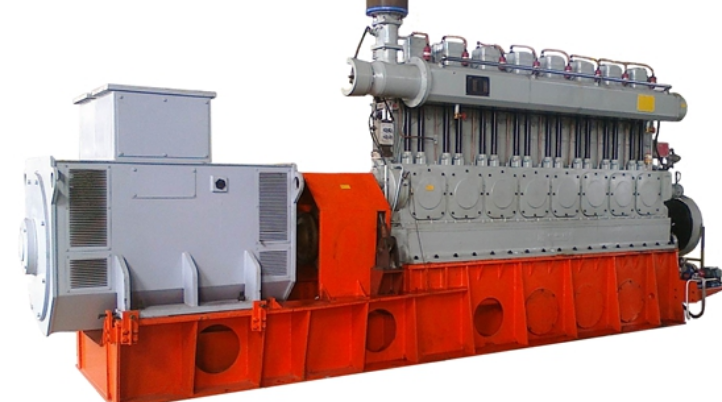

脱硫器、脱硫塔、沼气脱硫器沼气处置工艺:

Biogas disposal technology of desulfurizer, desulfurizer and biogas desulfurizer:

沼气从厌氧发酵安装产出时,特别是在中温或低温发酵时,携带有少量的H2S 。沼气脱硫器由于沼气中还有少量的水蒸汽存在,水与沼气中的H2S 共同作用,减速了金属管道、阀门和流量计的腐蚀和梗塞。另外, H2S 熄灭后生成的SO2 ,与熄灭产物中的水蒸气结分解亚硫酸,使设备的金属外表发生腐蚀,并且还会形成对大气环境的净化,影响人体安康。因而,在运用沼气之前,必需运用沼气脱硫器脱除其中的H2S 。

When biogas is installed and produced from anaerobic fermentation, especially at medium or low temperature, it carries a small amount of H2S. Due to the presence of a small amount of water vapor in biogas, the corrosion and obstruction of metal pipes, valves and flowmeters are slowed down by the interaction of water and H2S in biogas. In addition, SO2 produced after H2S extinguishing decomposes sulfite with water vapor in extinguishing products, which corrodes the metal appearance of the equipment, and also forms the purification of atmospheric environment, affecting human health. Therefore, before using biogas, it is necessary to use biogas desulfurizer to remove H2S.

脱硫器、脱硫塔、沼气脱硫器污染工艺流程 :

Pollution process of desulfurizer, desulfurizer and biogas desulfurizer:

从厌氧沼气池中出来的沼气中含有少量的水气、粉尘杂质、硫化氢等无害气体。沼气经过初步脱水除尘后然后进入脱硫塔,应用合理的反响条件可经济地将沼气中的硫化氢脱200ppm以下,脱硫后的沼气进入沼气增压风机停止增压保送,增压后的沼气进入缓冲零碎停止缓冲,一方面停止沼气除杂处置,另一方面波动送气压力,以保证后续发电机组的波动运转,缓冲稳压后的沼气进入终端用气设备。

The biogas from anaerobic digester contains a small amount of harmless gases such as water, dust impurities and hydrogen sulfide. After dehydration and dust removal, biogas enters the desulfurization tower. Reasonable reaction conditions can economically remove hydrogen sulfide from biogas below 200 ppm. After desulfurization, biogas enters the booster fan of biogas to stop boosting and delivering. After boosting, biogas enters the buffer fragmentally and stops buffering. On the one hand, it stops the disposal of biogas impurities, on the other hand, it fluctuates the delivering pressure to ensure the subsequent generators. Group fluctuation operation, buffering and stabilizing the methane into the terminal gas equipment.

To sum up, Shandong Heneng Environmental Protection Energy Equipment Co., Ltd. provides more knowledge of biogas desulfurization. Welcome to our website: http://www.fcw-app.com. Thank you for your support!